Injection Molding System Solutions

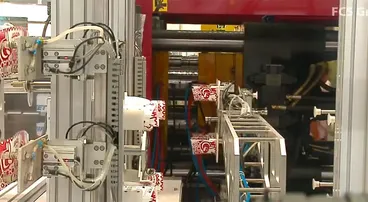

In-Mold Labeling Turnkey Solution

In-mold labeling (IML) is an efficient production technique that integrates labeling directly into the injection molding process. Pre-printed labels are placed inside the mold, and during the injection molding process, the plastic material fuses with the label.

See More

Beverage Packaging Injection Molding Solution

The beverage industry has embraced diverse packaging options beyond traditional glass containers. PET plastic, favored for its lightweight, durability, and cost-effectiveness, now dominates packaging for carbonated drinks, juices, teas, and bottled water.

See More

Microcellular Foaming Injection Molding Solution

Microcellular foaming injection molding is a plastic processing technique that enhances the production of plastic parts by introducing gas (N2 or CO2) into the melted plastic material. By pressurizing the gas to a supercritical state, it is mixed with the molten plastic to form a single-phase solution.

See More

Solution for High Precision Injection Molds

To provide comprehensive services, FCS has been assisting customers in designing and producing high-precision plastic molds for many years. We have continuously developed related technologies, including CAD, CAM, CAE, FMS, and FMC.

See More

Turnkey Solution for Injection Molding Plant

At FCS, we prioritize customer satisfaction by offering more than just high-quality products and services. Our turnkey solutions provide a complete package for setting up and optimizing injection molding plants. With our expert team’s extensive knowledge and experience, we tailor solutions to meet the unique needs and diverse product characteristics of each customer.

See More