At FCS, we specialize in providing advanced injection molding equipment tailored for manufacturing various automotive components. Our plastic molding machinery is capable of molding everything from intricate interior features and sleek exterior panels to durable vehicle lighting systems. By prioritizing precision and flexibility, our injection molding equipment helps manufacturers meet stringent industry standards for aesthetics, safety, and reliability.

Front Grill

Front Grill Dashboard

Dashboard Door Trim Panel

Door Trim Panel Quarter Window Frame

Quarter Window Frame Tri-Color Tail Light

Tri-Color Tail Light Two-Color Tail Light

Two-Color Tail Light Two-Color Tail Light

Two-Color Tail Light Daytime Running Light Guide Bar

Daytime Running Light Guide Bar Traffic Cone

Traffic Cone Bicycle Pedal

Bicycle Pedal Car Fender

Car Fender Helmet

Helmet Car Bumper

Car Bumper Motorcycle Fender

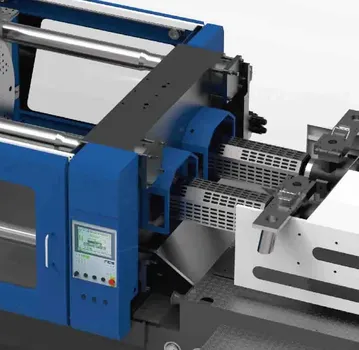

Motorcycle FenderWith clamping forces ranging from 350 to 3500 tons, this injection molding equipment is engineered to enhance output while maintaining precise control over large-scale production processes.

Read MoreThe injection unit consists of two independent sets of material tubes that operate synchronously, ensuring precise control over mold opening, closing, and injection travel, achieving dual-color molding in one cycle with precision up to 0.1mm. The clamping force ranges from 160 to 1900 tons.

Read MoreIt employs advanced linear guides that reduce friction during the mold opening and closing, enhancing operational speed and efficiency. This two-platen injection molding equipment can easily handle complex tasks, ensuring accurate and consistent production with clamping forces ranging from 1000 to 2900 tons.

Read MoreGet in touch with us using our contact form. Our team will get back to you as soon as possible.

Please select your industry. And check out how we anticipate trends in your market.

All industries