- Home

- Products & System

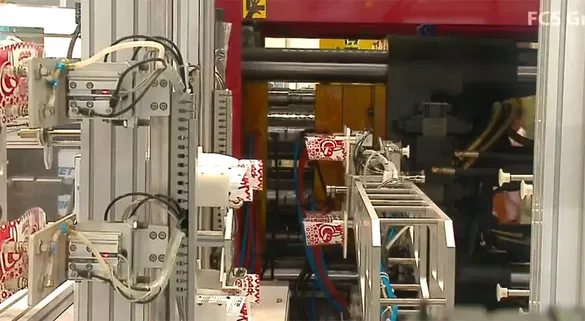

Plastic Injection Molding System

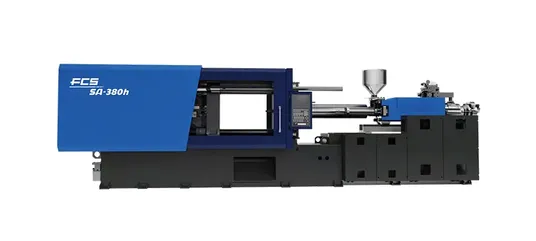

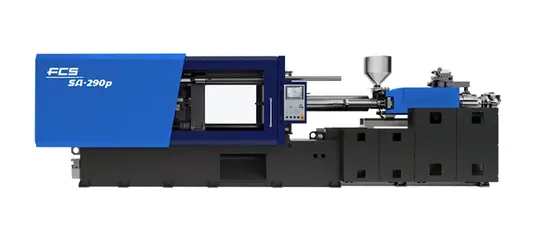

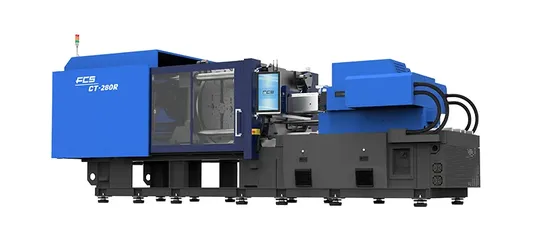

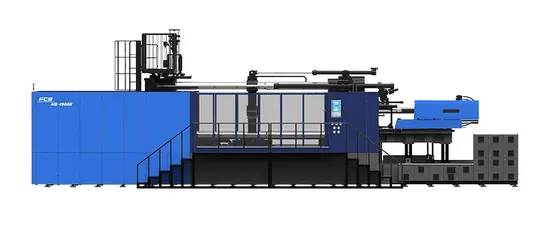

FCS specializes in the production and sale of precision injection molding machines, offering a diverse range of models with clamping forces from 50 to 4000 tons. Our plastic molding machines are designed to meet the needs of various industries, providing reliable and efficient solutions for manufacturing high-quality plastic components. With a commitment to innovation and excellence, we ensure that each machine delivers optimal performance and precision

Injection Molding System Solution

Injection Molding System Solution