FCS offers injection molding machines designed to produce precise optical components like lenses, light covers, and light guide plates. Our molding equipment meets the high standards required in the optical industry, ensuring each product is made with great accuracy and cleanliness. By using the latest technology, our injection molding machines offer consistent quality, making them perfect for applications that demand top-level precision and performance.

We are committed to providing advanced injection molding solutions that ensure precision and cleanliness for the optical industry, supporting the production of high-quality lenses, light covers, and more.

Optical Glasses

Optical Glasses Industrial Safety Lenses

Industrial Safety Lenses Goggles

Goggles Fresnel Lens

Fresnel Lens Monitor Camera Enclosure

Monitor Camera Enclosure LED Light Housing

LED Light Housing Automotive Optical Lens

Automotive Optical Lens Light Guide Plate

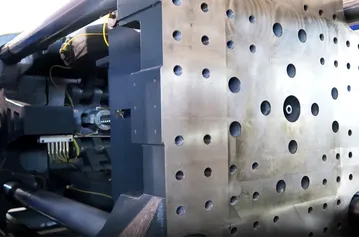

Light Guide PlateThe clamping force of this molding machine is adaptable, ranging from 100 to 1600 tons, making it suitable for a wide array of injection molding tasks.

Read MoreClamping forces are adjustable between 60 and 530 tons, making this injection machine suitable for various industrial applications.

Read MoreWith injection control accuracy reaching as fine as 0.01mm and clamping forces ranging from 50 to 900 tons, horizontal injection molding machine can handle a wide range of production requirements.

Read MoreGet in touch with us using our contact form. Our team will get back to you as soon as possible.

Please select your industry. And check out how we anticipate trends in your market.

All industries