FCS offers a comprehensive range of injection molding machines suitable for efficiently producing packaging containers. Whether you need to manufacture disposable food containers, cosmetic packaging, or household chemical bottles, our injection molding machines ensure high-volume production with consistent quality and reliability.

Two-Color Multi-Compartment Meal Tray

Two-Color Multi-Compartment Meal Tray Lunch Box

Lunch Box Plastic Takeout Container

Plastic Takeout Container Thin-Wall Container

Thin-Wall Container Disposable Plastic Cutlery

Disposable Plastic Cutlery Thin-Wall Container

Thin-Wall Container Bottle Caps

Bottle Caps Food Packaging Closures

Food Packaging Closures Two-Color Non-Spill Bottle Cap

Two-Color Non-Spill Bottle Cap Disposable Plastic Cup

Disposable Plastic Cup Cold Water Kettle

Cold Water Kettle PET Preforms

PET Preforms PET Bottles

PET Bottles IML Yogurt Cups

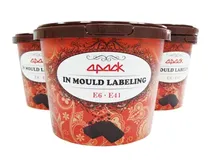

IML Yogurt Cups IML Ice Cream Container

IML Ice Cream Container IML Yogurt Cups

IML Yogurt Cups IML Water Cups

IML Water Cups Plastic Tableware

Plastic Tableware Two-Color Bowls

Two-Color Bowls Colored Plastic Cups

Colored Plastic Cups Multi-Colored Utensil

Multi-Colored Utensil Cosmetic Containers

Cosmetic Containers Two Color Flip Top Cap

Two Color Flip Top Cap IML Yogurt Cup with Lid & Spoon

IML Yogurt Cup with Lid & Spoon Fine Mist Spray Bottle

Fine Mist Spray Bottle Paint Bucket

Paint BucketWith the ability to manage clamping forces from 200 to 750 tons, it is versatile enough to handle both small boutique orders and large commercial runs.

Read MoreIt features a proportional valve structure for rapid response and precise positioning with cycle times as short as 1 ms. Temperature variations are tightly controlled within ±1°C using PID temperature control, and the clamping force ranges from 170 to 600 tons.

Read MoreWith injection control accuracy reaching as fine as 0.01mm and clamping forces ranging from 50 to 900 tons, horizontal injection molding machine can handle a wide range of production requirements.

Read MoreGet in touch with us using our contact form. Our team will get back to you as soon as possible.

Please select your industry. And check out how we anticipate trends in your market.

All industries