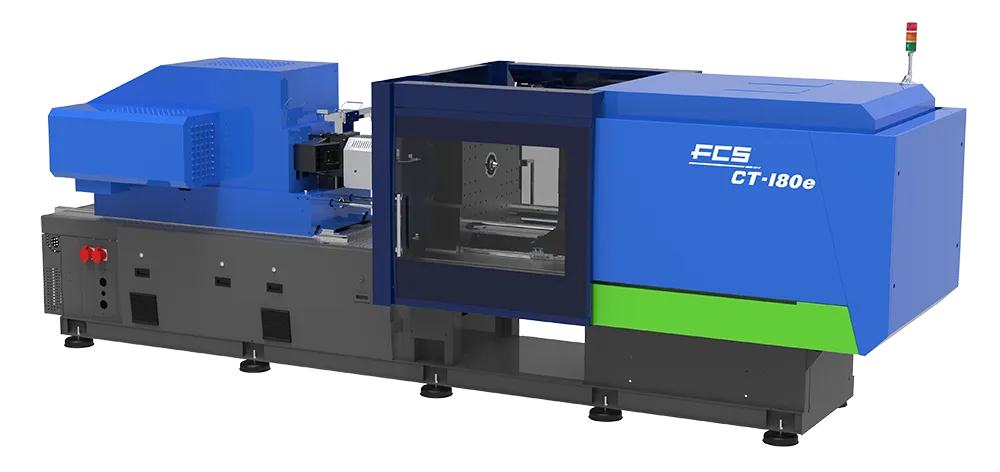

Designed to produce precision parts across various industries efficiently, this all-electric injection molding machine combines advanced servo motor technology with a ball screw and rigid membrane system for rapid and precise operation. Its molding process is stabilized by a four-pillar frame structure that evenly distributes stress, ensuring smooth and consistent injection molding. With injection control accuracy reaching as fine as 0.01mm and clamping forces ranging from 50 to 900 tons, horizontal injection molding machine can handle a wide range of production requirements.

Suitable for producing precision parts in industries that require high accuracy and cleanliness. It is used for making food packaging, optical components, and medical products, where consistent quality is essential. The injection molding machine also handles the production of computer peripherals, printer casings, and office machine parts effectively. Additionally, it can produce plastic frames and lenses, demonstrating its flexibility across various manufacturing tasks.

Samples of Plastic Injection Molded Parts Syringe

Syringe

Blood Collection Tube

Blood Collection Tube

Petri Dish

Petri Dish

Tablet Case

Tablet Case

Wire Connector

Wire Connector

Light Guide Plate

Light Guide Plate

Significantly enhances operational speed by 30%-50%, reducing molding cycles and facilitating fast and smooth transitions. It incorporates a unique positioning system that achieves an exceptional precision level of 0.005°, ensuring the stability and accuracy required for intricate molded products.

Features multiple independent feeding systems that operate synchronously, dramatically shortening cycle times. Components like screws and barrels are crafted from special alloy steel treated with ion nitriding for improved resistance to corrosion, wear, and high temperatures, which contributes to the unit's durability and consistent performance.

| Model | Unit | | | ||||||||||||||

| Injection Unit | Type | - | 160H | 490H | 1000H | 2250 | 6900(OP) | ||||||||||

| Screw diameter | mm | 18 | 25 | 30 | 35 | 40 | 45 | 45 | 50 | 55 | 60 | 65 | 70 | 80 | 90 | 100 | |

| Screw stroke | mm | 130 | 190 | 245 | 325 | 470 | |||||||||||

| Theoretical shot volume | cm³ | 33 | 64 | 92 | 183 | 239 | 302 | 390 | 481 | 582 | 919 | 1078 | 1251 | 2362 | 2990 | 3691 | |

| Shot weight of injection (PS) | gram | 30 | 58 | 84 | 166 | 217 | 275 | 355 | 438 | 530 | 836 | 981 | 1138 | 2150 | 2721 | 3359 | |

| Injection pressure | kgf/cm² | 3000 | 2700 | 1900 | 2500 | 2000 | 1650 | 2600 | 2100 | 1738 | 2450 | 2088 | 1800 | 3038 | 2400 | 1982 | |

| Injection speed | mm/sec | 300 | 300 | 300 | 160 | 160 | |||||||||||

| Injection rate | cm³/sec | 76 | 147 | 212 | 289 | 377 | 477 | 477 | 589 | 713 | 452 | 531 | 616 | 804 | 1018 | 1257 | |

| Max. screw rotation speed | rpm | 350 | 300 | 300 | 250 | 200 | |||||||||||

| Mold Clamping Unit | Mold clamping force | tonf | 50 | 150 | 280 | 550 | 900 | ||||||||||

| Mold clamping stroke | mm | 250 | 430 | 570 | 900 | 1200 | |||||||||||

| Mold thickness | mm | 160~430 | 200~620 | 250~730 | 380~900 | 450~1100 | |||||||||||

| Suggested min. mold diameter (H×V) | mm | 240×240 | 340×340 | 470×470 | 660×660 | 795×795 | |||||||||||

| Tie bar spacing (H×V) | mm | 370×370 | 520×520 | 720×720 | 1020×1020 | 1220×1220 | |||||||||||

| Mold platen (H×V) | mm | 535×535 | 755×720 | 1010×950 | 1350×1420 | 1710×1710 | |||||||||||

| Ejector stroke | mm | 100 | 140 | 150 | 220 | 230 | |||||||||||

| Ejector force | tonf | 2.0 | 3.0 | 5.0 | 14.0 | 24.0 | |||||||||||

| Electrical Equipment | Main power | kW | 11.8 | 13 | 15 | 31.5 | 33 | 33 | 53 | 55 | 55 | 80 | 80 | 80 | 175 | 175 | 175 |

| Temperature controller | set | 4 | 4 | 4 | 5 | 5 | 5 | 6 | 6 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | |

| Heater capacity | kW | 4.0 | 4.0 | 6.1 | 11.3 | 11.3 | 14.3 | 19.4 | 19.4 | 25.9 | 32.8 | 32.8 | 45.9 | 80.0 | 80.0 | 80.0 | |

| General | Machine dimensions (L×W×H) | mm | 4200×1400×1750 | 5700×1600×1900 | 7250×1900×2100 | 9800×2400×2900 | 12400×2900×2900 | ||||||||||

| Machine weight | ton | 4 | 7.5 | 15.5 | 30 | 56 | |||||||||||

Fu Chun Shin, since 1974, is the leading brand of injection molding machine in Taiwan.