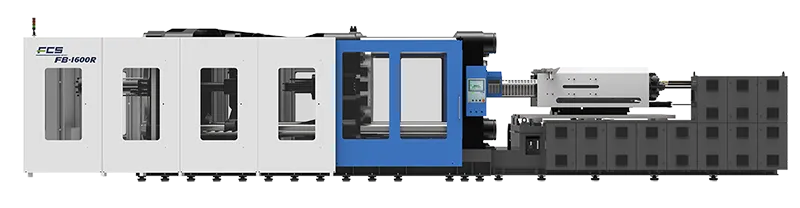

This large-scale injection molding machine is equipped with a rotary table that rotates 180°, allowing two molds to be placed simultaneously. This enables the production of sharply defined dual-color products. The injection unit consists of two independent sets of material tubes that operate synchronously, ensuring precise control over mold opening, closing, and injection travel, achieving dual-color molding in one cycle with precision up to 0.1mm. The clamping force ranges from 160 to 1900 tons.

Ideal for producing automotive components, sporting goods, consumer products, and various water supply materials.

Samples of Plastic Injection Molded Parts Two-Color Tail Light

Two-Color Tail Light

Tri-Color Tail Light

Tri-Color Tail Light

Refrigerator Inner Panel

Refrigerator Inner Panel

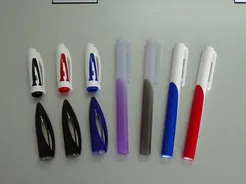

Pen cap

Pen cap

Pen barrel

Pen barrel

Electric shaver shell

Electric shaver shell

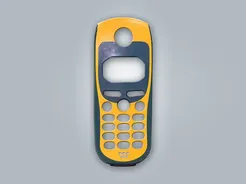

Mobile phone housing

Mobile phone housing

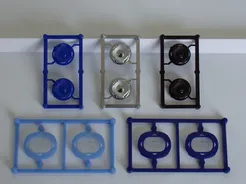

Press buttons

Press buttons

The turntable features industry-leading technology with dual neutron devices and a mold cooling system that prevents contact with the mold plate during rotation, minimizing wear and avoiding malfunctions. The injection molding system conducts a self-check after rotation before clamping, ensuring mold safety. This design includes a patented, precision rotary positioning system and clamping fixtures operated by an energy-efficient servo system, resulting in stable and precise molding.

The injection unit significantly reduces cycle times by combining two independent material tubes that operate synchronously. Made from specially treated foreign alloy steel, these components resist corrosion, wear, and high temperatures. The PID temperature control system includes features such as cold-start prevention for the screw, wire break detection, and maintains temperature variations within ±1°C.

| Model | Unit | |||||||||||||||||||||||

| Injection Unit | Type | - | 141 | 201 | 401 | 611 | 1301 | 1301 | 3261 | 3261 | 5001 | |||||||||||||

| Screw diameter | mm | 22 | 24 | 26 | 26 | 28 | 30 | 32 | 32 | 36 | 40 | 45 | 40 | 45 | 50 | 55 | 50 | 60 | 70 | 60 | 70 | 80 | 90 | |

| Screw stroke | mm | 124 | 137 | 200 | 220 | 286 | 286 | 340 | 400 | 340 | 400 | 450 | 450 | |||||||||||

| Theoretical shot volume | cm³ | 47 | 56 | 66 | 73 | 84 | 97 | 110 | 161 | 203 | 251 | 318 | 276 | 350 | 561 | 679 | 561 | 961 | 1539 | 961 | 1539 | 2261 | 2861 | |

| Shot weight of injection (PS) | 9 | 43 | 51 | 60 | 66 | 77 | 88 | 100 | 146 | 185 | 229 | 289 | 251 | 318 | 511 | 618 | 511 | 874 | 1400 | 874 | 1400 | 2057 | 2604 | |

| Injection pressure | kgf/cm² | 2929 | 2461 | 2097 | 2791 | 2406 | 2096 | 1842 | 2529 | 1998 | 1619 | 1279 | 2205 | 1742 | 2240 | 1851 | 2240 | 2882 | 2117 | 2882 | 2117 | 2198 | 1737 | |

| Injection rate | g/s | 66 | 78 | 92 | 70 | 81 | 93 | 106 | 154 | 194 | 240 | 304 | 221 | 280 | 218 | 264 | 218 | 278 | 378 | 339 | 461 | 489 | 619 | |

| Distance between barrel centers | mm | 400 | 400 | 650 | 710 | 710 | ||||||||||||||||||

| Mold Clamping Unit | Mold clamping force | tonf | 160 | 550 | 1250 | 1900 | ||||||||||||||||||

| Mold clamping stroke | mm | 320 | 600 | 1200 | 1400 | |||||||||||||||||||

| Mold thickness | mm | 200~550 | 320~800 | 600~1400 | 700~1700 | |||||||||||||||||||

| Tie bar spacing (H×V) | mm | 730×400 | 1196×660 | 1360×1210 | 1650×1550 | |||||||||||||||||||

| Mold platen (H×V) | mm | 960×630 | 1610×1065 | 1840×1740 | 2430×2340 | |||||||||||||||||||

| Effective ejector stroke | mm | 70 | 150 | 140 | 275 | |||||||||||||||||||

| Ejector force | tonf | 4.0×2 | 10.0×2 | 17.2×2 | 24.7×2 | |||||||||||||||||||

| Rotary table diameter | mm | 810 | 1300 | 1800 | 2250 | |||||||||||||||||||

| Max. rotary diameter of mold | set | 850 | 1410 | 1900 | 2365 | |||||||||||||||||||

| Electrical Equipment | Max. pump driving motor | kW | 13+13 | 30+30 | 30 | 30+22 | 30+30 | 45+30 | ||||||||||||||||

| Temperature controller | set | 4 | 5 | 5 | 5 | 6 | 6 | 6 | 6 | 6 | ||||||||||||||

| Heater capacity | kW | 8.7 | 10.9 | 19.3 | 28.3 | 36.4 | 18.2 | 22 | 39 | 22 | 39 | 50.7 | ||||||||||||

| General | Machine dimensions (L×W×H) | mm | 5785×1730×1870 | 8630×2800×2260 | 12750×3010×2700 | 14500×3500×3100 | ||||||||||||||||||

| Oil tank capacity | liter | 410 | 1040 | 1580 | 2500 | |||||||||||||||||||

| Machine weight | ton | 7.2 | 30 | 60 | 130 | |||||||||||||||||||

| Max. system pressure | kgf/cm² | 140 | 140 | 140 | 140 | |||||||||||||||||||

Fu Chun Shin, since 1974, is the leading brand of injection molding machine in Taiwan.