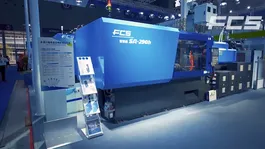

The thin-wall injection molding machine is a newly launched product manufactured by FCS, designed specifically for producing thin-walled packaging. This injection molding equipment integrates a high-performance servo-hydraulic system, which enables energy savings of 30%-70%. It features a proportional valve structure for rapid response and precise positioning with cycle times as short as 1 ms. Temperature variations are tightly controlled within ±1°C using PID temperature control, and the clamping force ranges from 170 to 600 tons.

Ideal for injection molding of food packaging, plastic trays, plastic cups, and plastic medical products.

Samples of Plastic Injection Molded Parts IML Chocolate Bucket with Lid

IML Chocolate Bucket with Lid

Disposable Plastic Cutlery

Disposable Plastic Cutlery

Disposable Plastic Cup

Disposable Plastic Cup

Bento box

Bento box

Sauce cup

Sauce cup

Take-out box

Take-out box

Blood collection tube

Blood collection tube

Standard equipped with infrared nano heaters for rapid heating, excellent heat retention, and over 30% energy savings. Utilizes PID temperature control to maintain accuracy within ±1°C. Features a large L/D ratio and high-mixing screw for superior plasticization efficiency.

Standard equipped with the KEBA control system. Offers an operation mode scan cycle within 1ms. Designed with an ergonomic layout. Includes comprehensive data and image monitoring functions.

| Model | Unit | |||||

| Injection Unit | Type | - | 400 | 770 | 1000 | 1100 |

| Screw diameter | mm | 40 | 50 | 58 | 60 | |

| Screw stroke | mm | 190 | 230 | 230 | 230 | |

| Theoretical shot volume | cm³ | 239 | 452 | 608 | 650 | |

| Shot weight of injection (PS) | gram | 217 | 411 | 553 | 592 | |

| Injection pressure | kgf/cm² | 1663 | 1710 | 1707 | 1712 | |

| Injection speed | mm/seo | 365 | 395 | 475 | 515 | |

| Injection rate | cm3/sec | 460 | 778 | 1260 | 1459 | |

| Mold Clamping Unit | Mold camping force | tonf | 170 | 290 | 460 | 600 |

| Mold camping stroke | mm | 430 | 550 | 750 | 820 | |

| Mold thickness | mm | 180~520 | 220~580 | 280~730 | 300~850 | |

| Tie bar spacing (H×V) | mm | 470×410 | 580×515 | 720×720 | 830×750 | |

| Mold platen (H×V) | mm | 745×655 | 875×875 | 1090×1090 | 1230×1150 | |

| Ejector stroke | mm | 135 | 140 | 140 | 180 | |

| Ejector force | tonf | 6.7 | 8.8 | 8.8 | 13 | |

| Electrical Equipment | Max. pump driving motor | kW(380V) | 58 | 46.2+46.2 | 63.5+63.5 | 63.5+63.5+37 |

| Heater capacity | kW | 10 | 20.4 | 32.6 | 33 | |

| General | Machine dimensions (L×W×H) | mm | 4900×1430×2100 | 6590×1630×2120 | 7850×1950×2080 | 8610×2170×2200 |

| Oil tank capacity | liter | 260 | 500 | 580 | 630 | |

| Machine weight | ton | 5.5 | 11 | 18.5 | 26 | |

Fu Chun Shin, since 1974, is the leading brand of injection molding machine in Taiwan.