The beverage industry has embraced diverse packaging options beyond traditional glass containers. PET plastic, favored for its lightweight, durability, and cost-effectiveness, now dominates packaging for carbonated drinks, juices, teas, and bottled water. In response to the growing demand for various plastic containers, we offer comprehensive injection molding solutions tailored for the beverage packaging sector.

FCS provides complete solutions for beverage packaging, covering every stage from preform and cap production to bottle blow molding and filling. We optimize each step to enhance efficiency and quality, reducing costs and boosting productivity. Our services include equipment supply, mold design, automation systems, mass production technology, and full factory planning to ensure smooth integration and operation.

Fu Chun Shin, since 1974, is the leading brand of injection molding machine in Taiwan.

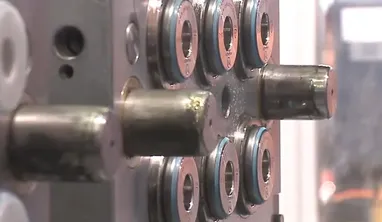

The clamping force of this molding machine is adaptable, ranging from 100 to 1600 tons, making it suitable for a wide array of injection molding tasks.

Temperature variations are tightly controlled within ±1°C using PID temperature control, and the clamping force ranges from 170 to 600 tons.

It controls temperatures with exceptional precision within ±1℃ using a PID system and operates with a fast scanning cycle under 1ms. The clamping force is capable of reaching between 220 to 1,000 tons.