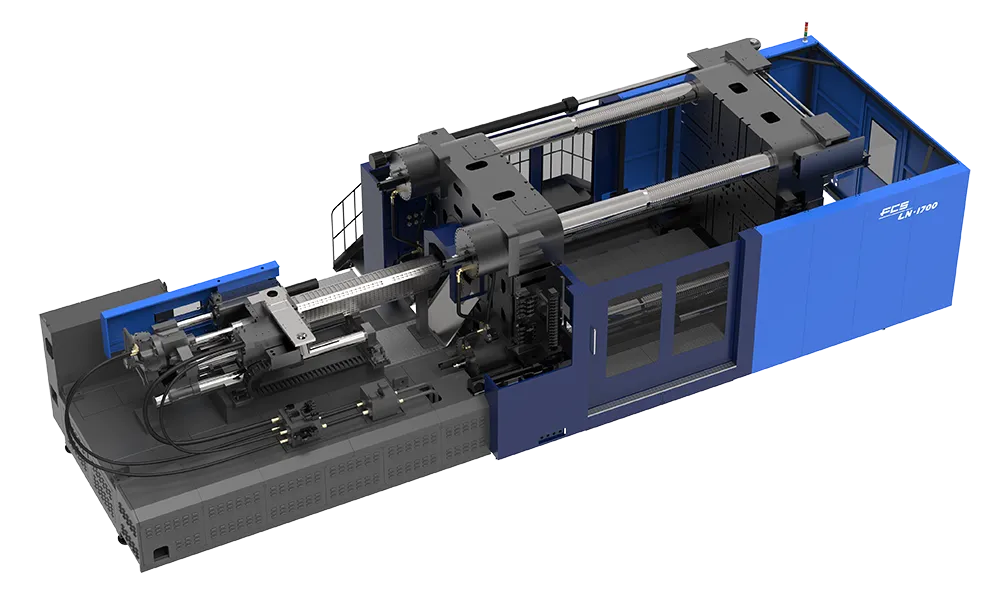

Designed to mold medium to large plastic parts efficiently, this two-platen injection molding machine integrates features that boost its performance and usability. The plastic injection molding machine uses low-friction linear guides for mold locking, speeding up both the mold opening and closing processes. A screw, specially designed with a high L/D ratio, enhances the plasticizing capabilities, allowing for consistent and effective molding. Linear guides support the lock mold and injection platform, reducing resistance and wear and providing smooth operation with precise mold locking accuracy of up to ±1%. This plastic injection machine handles clamping forces from 500 to 4000 tons, suitable for a wide range of molding tasks.

The injection molding machine is perfect for manufacturing large plastic items such as automotive bumpers, dashboard components, and air conditioning compressor casings. It is also suitable for producing heavy-duty plastic pallets for loads exceeding 3000 tons, demonstrating its capability to handle diverse industrial molding needs.

Samples of Plastic Injection Molded Parts Car Fender

Car Fender

Car Bumper

Car Bumper

Traffic Cone

Traffic Cone

Washer Inner Tub

Washer Inner Tub

Storage Box

Storage Box

Plastic Rattan Sofa

Plastic Rattan Sofa

Pipe

Pipe

Stool

Stool

Storage box

Storage box

Interior panel

Interior panel

Car interior

Car interior

Car bumper

Car bumper

| Model | UNIT | ||||||||||||||||

| Injection Unit | Type | - | 4600 | 5900 | 7000 | 8200 | 10300 | ||||||||||

| Screw diameter | mm | 75 | 85 | 95 | 85 | 95 | 105 | 95 | 100 | 110 | 100 | 110 | 120 | 110 | 120 | 130 | |

| Injection stroke | mm | 420 | 430 | 450 | 495 | 540 | |||||||||||

| Theoretical shot volume | cm³ | 1855 | 2382 | 2976 | 2439 | 3046 | 3721 | 3188 | 3533 | 4274 | 3886 | 4702 | 5595 | 5129 | 6104 | 7164 | |

| Shot weight of injection (PS) | gram | 1688 | 2168 | 2708 | 2219 | 2772 | 3387 | 2901 | 3215 | 3890 | 3536 | 4279 | 5092 | 4668 | 5555 | 6519 | |

| Injection pressure | kgf/cm² | 2466 | 1920 | 1537 | 2445 | 1957 | 1602 | 2199 | 1985 | 1640 | 2117 | 1749 | 1470 | 2008 | 1687 | 1438 | |

| Injection speed | mm/sec | 123 | 126 | 112 | 105 | 106 | |||||||||||

| Injection rate | cm³/sec | 495 | 636 | 794 | 649 | 811 | 991 | 722 | 800 | 968 | 750 | 907 | 1080 | 912 | 1085 | 1274 | |

| Mold Clamping Unit | Mold clamping force | tonf | 500 | 1100 | |||||||||||||

| Mold clamping stroke | mm | 1250/750 | 2050/1400 | ||||||||||||||

| Mold thickness | mm | 400~900 | 600~1250 | ||||||||||||||

| Max. weight of mold | tonf | 5 | 13 | ||||||||||||||

| Daylight | mm | 1650 | 2650 | ||||||||||||||

| Suggested min mold diameter (H×V) | mm | 640×570 | 875×785 | ||||||||||||||

| Tie bar spacing (H×V) | mm | 910×810 | 1250×1120 | ||||||||||||||

| Mold platen (H×V) | mm | 1380×1280 | 1800×1680 | ||||||||||||||

| Ejector stroke | mm | 250 | 350 | ||||||||||||||

| Ejector force | tonf | 11 | 23.9 | ||||||||||||||

| Electrical Equipment | Max. pump driving motor | kW | 45*2 | 45+30*2 | 45+30*2 | 45+30*2 | 45*3 | ||||||||||

| Temperature controller | (range)set | (0-400C)×8 | (0-400℃)×8 | ( 0-400℃)×8 | ( 0-400℃)×8 | ( 0-400C)×8 | |||||||||||

| Heater capacity | kW | 37.55 | 43.77 | 46.27 | 51.29 | 63.38 | |||||||||||

| General | Machine dimensions (L×W×H) | mm | 8200×2700×2200 | 11400×3400×2650 | |||||||||||||

| Oil tank capacity | liter | 1210 | 2250 | ||||||||||||||

| Machine weight | metric tons | 26 | 70 | ||||||||||||||

| Max. system pressure | kgf/cm² | 140 | 140 | 140 | 140 | 140 | |||||||||||

Fu Chun Shin, since 1974, is the leading brand of injection molding machine in Taiwan.