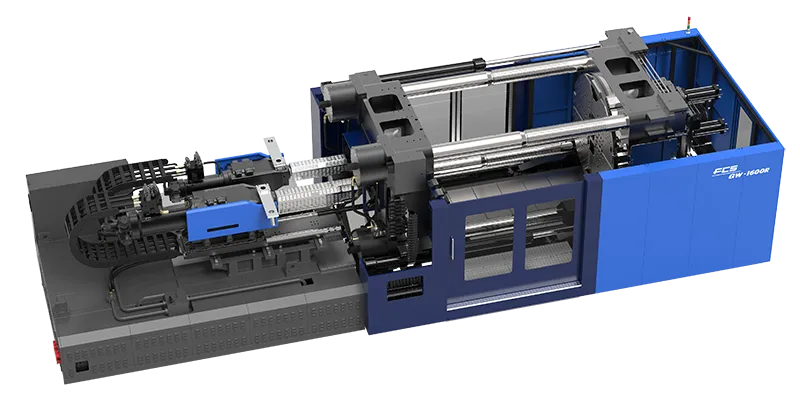

Our plastic injection equipment is designed to manufacture large, multi-colored components with precision. It employs advanced linear guides that reduce friction during the mold opening and closing, enhancing operational speed and efficiency. This two-platen injection molding equipment can easily handle complex tasks, ensuring accurate and consistent production with clamping forces ranging from 1000 to 2900 tons.

This two-platen multi-component injection molding machine is suitable for industries requiring large, complex parts such as automotive components, household appliances, and furniture. It stands out in applications like manufacturing integrated plastic light covers, car tail light covers, windows, and large automotive panels. Its capability to handle intricate multi-color and multi-material production makes it a valuable asset for manufacturers looking to innovate and enhance their product offerings.

This system ensures robust and reliable clamping, with smart pillar positioning to maintain strong lock mold force, which is crucial for producing precise and defect-free parts.

Designed using finite element analysis, the locking unit ensures even stress distribution across the molding machine and molds, prolonging their service life and enhancing the quality of the products.

Integrating a modern control system including Statistical Process Control (SPC) and remote monitoring capabilities enhances production management efficiency while ensuring mold longevity through protective features.

The servo-driven system reduces energy consumption by 30%-70%, demonstrating a commitment to eco-efficient practices without sacrificing performance.

Equipped with dual independent material tubes for synchronized injection actions, this setup reduces cycle times and increases throughput while specialized treatments on the screws and tubes minimize wear and corrosion.

The straight main piping reduces oil pressure loss, resulting in a more rational and aesthetically pleasing layout that simplifies installation and maintenance.

| Model | UNIT | |||||||||||||||||

| Injection Unit | Type | - | 1301 | 3261 | 1301 | 3261 | 5001 | 1301 | 3261 | 5001 | ||||||||

| Screw diameter | mm | 45 | 50 | 60 | 70 | 45 | 50 | 60 | 70 | 80 | 90 | 45 | 50 | 60 | 70 | 80 | 90 | |

| Injection stroke | mm | 286 | 286 | 340 | 400 | 286 | 286 | 340 | 400 | 450 | 450 | 286 | 286 | 340 | 400 | 450 | 450 | |

| Theoretical shot volume | cm³ | 455 | 561 | 961 | 1539 | 455 | 561 | 961 | 1539 | 2261 | 2861 | 455 | 561 | 961 | 1539 | 2261 | 2861 | |

| Shot weight of injection(PS) | g | 414 | 511 | 874 | 1400 | 414 | 511 | 874 | 1400 | 2057 | 2604 | 414 | 511 | 874 | 1400 | 2057 | 2604 | |

| Injection pressure | kgf/cm² | 2765 | 2240 | 2882 | 2117 | 2765 | 2240 | 2882 | 2117 | 2198 | 1737 | 2765 | 2240 | 2882 | 2117 | 2198 | 1737 | |

| Injection rate | g/s | 177 | 218 | 334 | 455 | 177 | 218 | 334 | 455 | 489 | 619 | 188 | 232 | 334 | 455 | 533 | 675 | |

| Distance between barrel centers | mm | 710 | 710 | 710 | ||||||||||||||

| Mold Clamping Unit | Mold clamping force | tonf | 1000 | 1600 | 2900 | |||||||||||||

| Mold clamping stroke | mm | 2200~1400 | 2400~1500 | 3500~2200 | ||||||||||||||

| Mold thickness | mm | 550~1350 | 700~1600 | 900~2200 | ||||||||||||||

| Tie bar spacing (H×V) | mm | 1260×1130 | 1530×1380 | 2300×1900 | ||||||||||||||

| Mold platen (H×V) | mm | 1860×1630 | 2200×2040 | 3200×2800 | ||||||||||||||

| Effective ejector stroke ① | mm | 200 | 200 | 300 | ||||||||||||||

| Ejector force | tonf | 46.2 | 46.2 | 46.2 | ||||||||||||||

| Rotary table diameter ② | mm | 1600 | 2030 | 2800 | ||||||||||||||

| Max. rotary diameter of mold | mm | 1770 | 2150 | 3100 | ||||||||||||||

| Electrical Equipment | Max. pump driving motor | kW | 30 | 45+30 | 30 | 45+30 | 45+30 | 52 | 52*2 | 52*2 | ||||||||

| Temperature controller | (range)set | (0-400℃)×6 | (0-400℃)×6 | (0-400℃)×6 | (0-400℃)×6 | (0-400℃)×6 | (0-400℃)×6 | (0-400℃)×6 | (0-400℃)×6 | |||||||||

| Heater capacity | kW | 18.2 | 22 | 39 | 18.2 | 20 | 39 | 50.7 | 18.2 | 22 | 39 | 50.7 | ||||||

| General | Machine dimensions (L×W×H) | mm | 11000×3600×3000 | 2270×3700×3160 | 15400×5060×4000 | |||||||||||||

| Oil tank capacity | liter | 2200 | 2200 | 2500 | ||||||||||||||

| Machine weight | ton | 65 | 90 | 175 | ||||||||||||||

| Max. system pressure | kgf/cm² | 140 | 140 | Mold clamping 175 / injection140 | ||||||||||||||

Fu Chun Shin, since 1974, is the leading brand of injection molding machine in Taiwan.

Its capability to exert clamping forces from 220 to 290 tons ensures it can effectively handle demanding medical production needs.