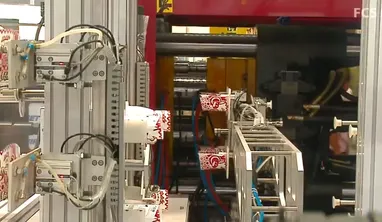

In-mold labeling (IML) is an efficient production technique that integrates labeling directly into the injection molding process. Pre-printed labels are placed inside the mold, and during the injection molding process, the plastic material fuses with the label. This results in a high-quality, durable, and seamlessly integrated label on the finished product. IML not only enhances the aesthetic appeal of products but also improves their durability and resistance to wear. It eliminates the need for additional post-production labeling steps, significantly reducing production time and costs.

Curved cups

Curved cups Octagonal cups

Octagonal cups Square container

Square container Customized product

Customized productFu Chun Shin, since 1974, is the leading brand of injection molding machine in Taiwan.

The injection unit consists of two independent sets of material tubes that operate synchronously, ensuring precise control over mold opening, closing, and injection travel, achieving dual-color molding in one cycle with precision up to 0.1mm. The clamping force ranges from 160 to 1900 tons.

It features a proportional valve structure for rapid response and precise positioning with cycle times as short as 1 ms. Temperature variations are tightly controlled within ±1°C using PID temperature control, and the clamping force ranges from 170 to 600 tons.

It controls temperatures with exceptional precision within ±1℃ using a PID system and operates with a fast scanning cycle under 1ms. The clamping force is capable of reaching between 220 to 1,000 tons.