Designed to meet the rigorous demands of hardware and electronic device manufacturing, the toggle clamping injection molding machine features excellent performance and stability. This plastic injection molding equipment stands out for its robust mold plate that distributes stress evenly, ensuring seamless operations. Its high-precision electronic scales maintain accuracy levels between 0.7% and 0.4%, and the efficient servo energy system offers substantial energy savings of 40%-70% while providing quick response dynamics. The clamping force of this molding machine is adaptable, ranging from 100 to 1600 tons, making it suitable for a wide array of injection molding tasks.

Ideal for producing general household hardware products, plastic electronic device components such as printer shells and computer accessories, automotive parts, plastic lenses, and frames, this plastic processing machine caters to a broad range of industrial needs.

Samples of Plastic Injection Molded Parts Helmet

Helmet

Spatula/Spoon

Spatula/Spoon

Ice Skates

Ice Skates

Chair

Chair

Blood collection tube

Blood collection tube

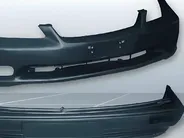

Car bumper

Car bumper

Interior panel

Interior panel

Bucket and lid

Bucket and lid

Pipe

Pipe

This intelligent system integrates the new FCS-6500S controller, featuring semi-closed or closed-loop hydraulic control. It offers a user-friendly graphical operation interface, real-time online curve monitoring, and centralized network link management, significantly enhancing the performance of the HN Series.

| Model | Unit | |||||||||||||

| Injection Unit | Type | - | 260 | 1600 | 4600 | 10300 | ||||||||

| Screw diameter | mm | 30 | 34 | 40 | 54 | 62 | 68 | 75 | 85 | 95 | 110 | 120 | 130 | |

| Injection stroke | mm | 150 | 280 | 420 | 540 | |||||||||

| Theoretical shot volume | cm³ | 106 | 136 | 188 | 641 | 845 | 1016 | 1855 | 2382 | 2976 | 5129 | 6104 | 7164 | |

| Shot weight of injection (PS) | g | 96 | 124 | 171 | 583 | 769 | 925 | 1688 | 2168 | 2708 | 4668 | 5555 | 6519 | |

| Injection pressure | kgf/cm² | 2481 | 1932 | 1396 | 2497 | 1894 | 1574 | 2466 | 1920 | 1537 | 2008 | 1687 | 1438 | |

| Injection speed | mm/s | 122 | 94 | 89 | 79 | |||||||||

| Injection rate | g/s | 79 | 101 | 140 | 196 | 258 | 310 | 356 | 458 | 572 | 681 | 810 | 951 | |

| Mold Clamping Unit | Mold clamping force | tonf | 100 | 300 | 600 | 1250 | ||||||||

| Mold clamping stroke | mm | 350 | 610 | 900 | 1275 | |||||||||

| Mold thickness | mm | 120~430 | 200~730 | 350~1100 | 450~1400 | |||||||||

| Suggested min. mold diameter (H×V) | mm | 234×234 | 397×397 | 560×560 | 880×790 | |||||||||

| Tie bar spacing | mm | 355×355 | 605×605 | 880×880 | 1360×1210 | |||||||||

| Mold platen | mm | 525×525 | 894×894 | 1310×1310 | 1840×1740 | |||||||||

| Ejector stroke | mm | 90 | 185 | 220 | 320 | |||||||||

| Ejector force | tonf | 2.7 | 8.9 | 15.8 | 21.5 | |||||||||

| Electrical Equipment | Max. pump driving motor | kW | 18 | 35.2 | 36.7+36.7 | 36.7×3 | ||||||||

| Temperature controller | set | 5 | 6 | 8 | 8 | |||||||||

| Heater capacity | kW | 7.0 | 19.9 | 37.55 | 63.4 | |||||||||

| General | Machine dimensions (L×W×H) | mm | 4830×1200×1580 | 7135×1738×1900 | 9670×2230×2145 | 13550×3010×2565 | ||||||||

| Oil tank capacity | liter | 310 | 580 | 1180 | 1860 | |||||||||

| Machine weight | ton | 3.5 | 12 | 29.5 | 66 | |||||||||

| Max. system pressure | kgf/cm² | 140 | 140 | 140 | 140 | |||||||||

Fu Chun Shin, since 1974, is the leading brand of injection molding machine in Taiwan.