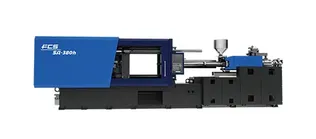

Rotary Table Two-Component Injection Molding Machine

This large-scale injection molding machine is equipped with a rotary table that rotates 180°, allowing two molds to be placed simultaneously. This enables the production of sharply defined dual-color products. The injection unit consists of two independent sets of material tubes that operate synchronously, ensuring precise control over mold opening, closing, and injection travel, achieving dual-color molding in one cycle with precision up to 0.1mm. The clamping force ranges from 160 to 1900 tons.

See MoreGet In Touch

Videos

Company Video

Company Video Plastic Injection Molding Machines at Exhibition

Plastic Injection Molding Machines at Exhibition Rotary Table Two-Component Injection Molding Machine

Rotary Table Two-Component Injection Molding Machine Thin-Wall Injection Molding Machine

Thin-Wall Injection Molding Machine All-Electric Injection Molding Machine

All-Electric Injection Molding Machine All-Electric Two-Component Injection Molding Machine

All-Electric Two-Component Injection Molding Machine Servo-Hydraulic Injection Molding Machine

Servo-Hydraulic Injection Molding Machine Large Rotary Table Two-Component Injection Molding Machine

Large Rotary Table Two-Component Injection Molding Machine Two-Platen Injection Molding Machine

Two-Platen Injection Molding Machine In-Mold Labeling (IML)

In-Mold Labeling (IML) Beverage Packaging Injection Molding

Beverage Packaging Injection Molding Microcellular Foaming Injection Molding

Microcellular Foaming Injection Molding Two-Platen Multi-Component Injection Molding Machine

Two-Platen Multi-Component Injection Molding Machine Bucket Injection Molding Machine

Bucket Injection Molding Machine NPE 2018, USA

NPE 2018, USA Chinaplas 2018, Shanghai

Chinaplas 2018, Shanghai Exhibition in Taipei in 2018

Exhibition in Taipei in 2018 K 2019, in Germany

K 2019, in Germany Chinaplas 2019 in Guangzhou

Chinaplas 2019 in Guangzhou Exhibition in 2019 in Indonesia

Exhibition in 2019 in Indonesia PVI 2020 in India

PVI 2020 in India

Injection Molding System Solution

Injection Molding System Solution